3D Printer

Modelmaking in the printing process

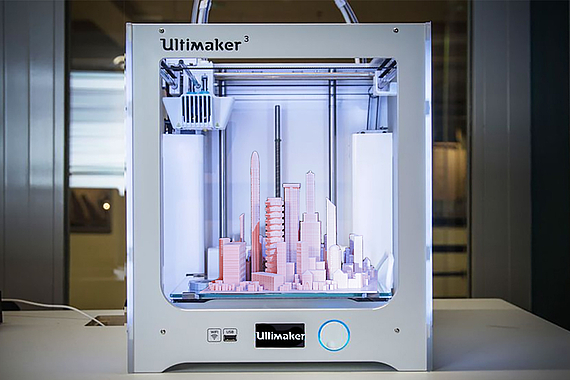

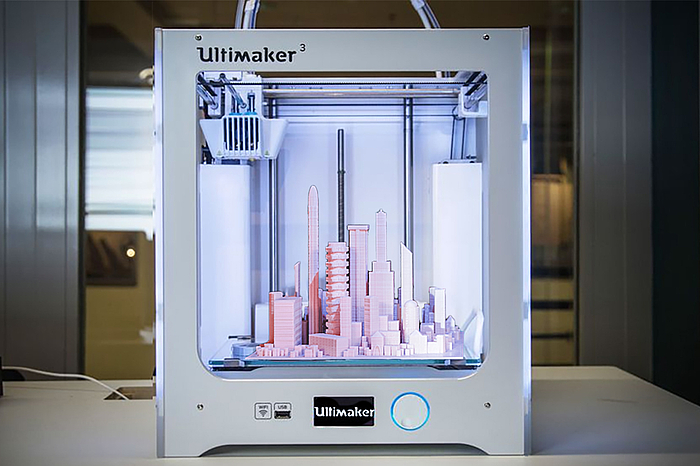

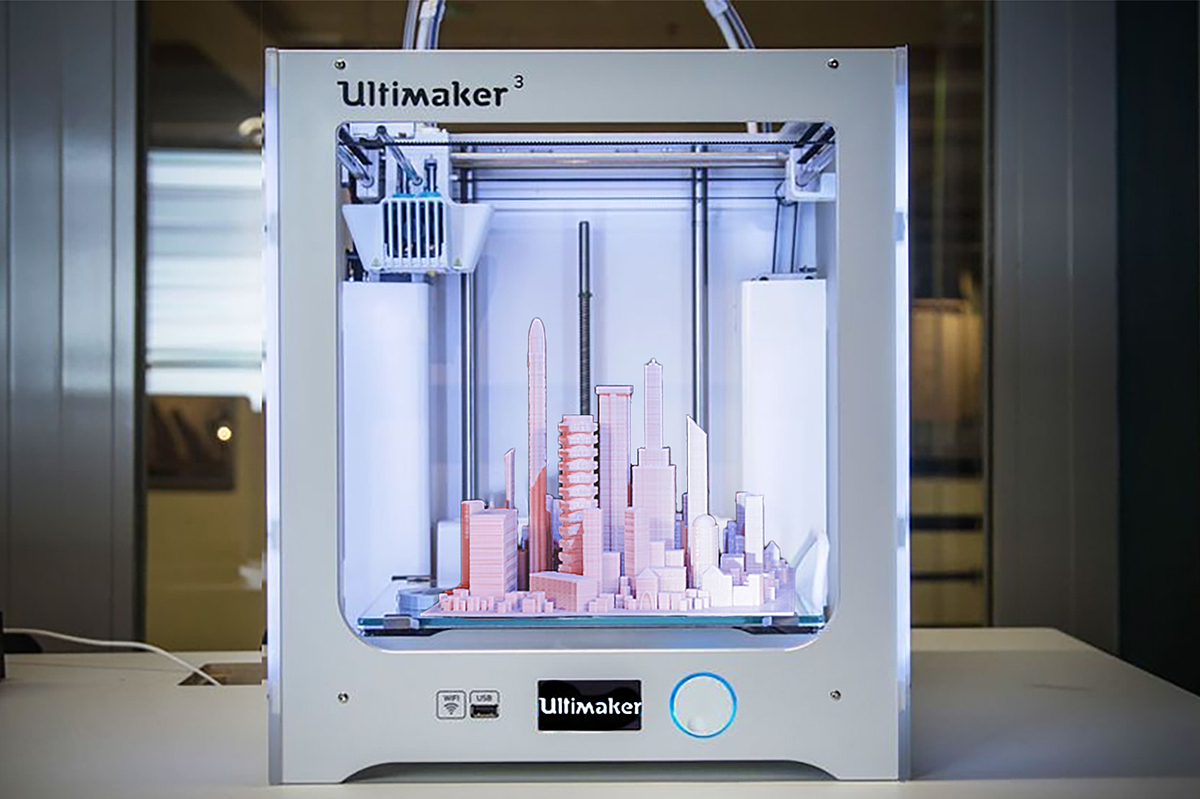

The faculty has had different 3D printers since 2009. Currently, students are offered 3D printing on Ultimakern S3 and S5.

These 3D printers print using the Fusion Deposit Method (FDM). Individual layers are printed on top of each other from hot thin plastic strands.

This method is suitable for scale architectural models, but also for functional prototypes, small series, tools or spare parts.

The 3D printing service is located in the basement of building 4201 (Herrenhäuserstraße 8) Trakt D in room D -104 in the service pool, directly opposite the model building workshop.

At the moment we do not have fixed opening hours, appointments can be arranged.

-

How does the order work?

You are welcome to send us an email with your university email to 3d-druck@archland.uni-hannover.de. Please make sure not to attach any files and follow the procedure below:

1. write an e-mail to 3d-druck@archland.uni-hannover.de with a date when your assignment should be ready and whether it is a normal final submission/intermediate submission or for Bachelor/Master.

2.we will send you a reply within 1-2 days if it is still feasible and a seafile link where you can upload your .stl file.

3.we write you if the file is printable, how much it will cost and how long it will take.

4.you tell us if you want it printed or not and we send it to print or not.

5. when the print is ready, we will make an appointment for you to pick it up and pay by debit card.

Waiting times at the end of the semester are of course longer and 3D prints for theses are prioritised from 6 weeks before the presentation. -

What is printed with?

Ultimaker S3 maximum print volume: 230mm x 190mm x 200mm

Ultimaker S5 maximum print volume: 330mm x 240mm x 300mm

Both printers can print PLA in black, white or transparent. Additionally there is support material for overhangs in the form of PLA and PVA (water soluble).Special requests are possible to a limited extent after consultation and are also priced differently.

-

How expensive is the printing?

The prices are derived from the weight of the model, printing time and number of print jobs of the printers. For the weight, both the actual weight of the model and that of the support material are calculated.